LED strip lights are extremely popular due to their versatility. The ability to cut LED strip lights to any desired length is certainly a huge innovation in lighting, and is generally quite straightforward to execute. But what happens when we need to go the other way, and span a larger distance of say, tens or even hundreds of meters with LED strip lights? This is where things can get a bit more challenging and will require a bit of layout planning and configuration.

For longer LED strip light runs, we typically look at three primary constraints when planning the length of each LED strip run:

1.The LED strip light's max run length specification

2.The power supply's maximum capacity specification

3.Electrical code considerations

Depending on the installation, one or more of these constraints may apply and act as the limiting factor in determining how long your LED strip sections can be. We discuss each of these constraints in detail below.

The LED Strip Light's Max Run Length Specification

First, the LED strip max run length is defined as the maximum permissible length of an LED strip connected to a single power source. This limitation is defined by the manufacturer and is typically notated on the specification sheet.

The maximum run length specification exists because of the way LED strip lights are designed and configured. Because LED strips are configured as a long and linear circuit board, any given point along the LED strip run must be capable of carrying the electrical current needed to power all of the downstream LEDs. This means that longer LED strip runs must carry a higher electrical current, particularly along the first few inches of the LED strip closest to the power source.

You will not want to exceed these maximum run length values under any circumstances. If any LED strip run were to be any longer than the max run length, this could potentially lead to voltage drop or other performance and safety issues.

Do solderless connectors and other wires count towards the maximum run length?

Wires and connectors do not count towards the maximum run length. For example, two 2.5mts LED strip sections tied together by a 3mts wire would span 8mts, but the LED strip sections do not exceed 5mts so this would not be exceeding the max run length specification.

Can I connect multiple LED strip runs in parallel, if the total LED strip length exceeds the max run length?

Yes, this would be permissible because none of the LED strip light sections would be subject to current levels above the maximum specification. A quick "test" would be to ask: does any part of the LED strip light have more than the max run length connected to it further downtream?

The Power Supply's Maximum Capacity Specification

For low voltage DC lighting systems, the power supply unit is a device that converts AC line voltage (e.g. 240volts or 120 volts) to low voltage DC (e.g. 24volts or 12 volts). The power supply unit has a maximum capacity that dictates how much electrical current it can convert from AC line voltage to low voltage DC at any given time. This is typically expressed in amps (A) or watts (W). We will use watts (W) in our example here for consistency. A common power capacity may be 120 watts (or expressed as 5 amps at 24 volts).

The primary rule here is that the power supply's capacity must be higher than the power draw of the LED strip run. Exceeding the capacity of the power supply's ability to provide power can damage the power supply unit and lead to potential safety issues.

The power supply's capacity is one of the first things that power supply manufacturers will note on the product datasheet and should be quite straightforward to determine. In some cases, you may need to convert watts to amps, and vice versa using the formula [Power (watts) = Current (amps) x Voltage (volts)]

Next, we'll need to determine the power draw of the LED strip run. Take a look at the LED strip light's datasheet, which will provide a specification for power draw, in watts per meter.

From there, simply multiply the power draw (in watts per meter) by the run length (meter). For example, the 10mts run length above would require 170watts ( 17watts * 10mts = 170watts ).

This means that at an absolute minimum, the power supply must have a capacity of 170 watts or higher, and ideally up to 20% overhead, meaning 204 watts would be the recommended minimum capacity for a 10mts run.

If the power supply unit that you have in mind does not have sufficient power capacity for a given LED strip run, you will need to either search for a higher capacity power supply, or reduce the LED strip run length and use multiple power supply units.

Can multiple power supply units be connected to a single wall-switch and dimmer?

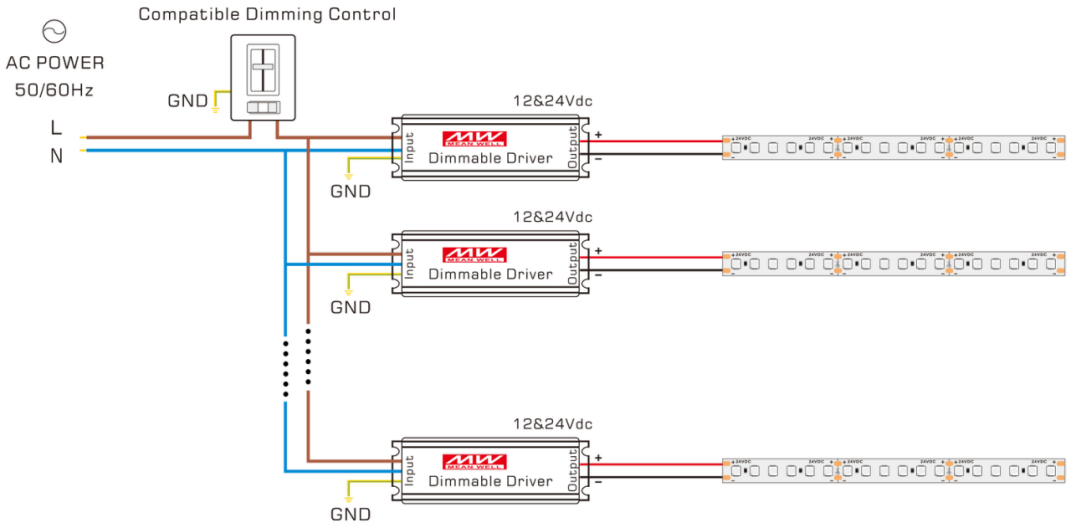

They certainly can! Since traditional wall switches and dimmers are installed on the AC line voltage side and permit multiple lights to be connected in parallel, the power supplies can also be connected in parallel to the same wall switch or dimmer. This is a nice feature that allows for multiple LED strip runs to be controlled from a single control point. Below is a layout diagram showing multiple LED strip runs connected to a single wall dimmer:

Electrical Code Considerations for Maximum LED Strip Run Length

The first two constraints we have discussed so far have to do with fundamental electricity principles. Depending on the type of installation as well as its level of permanence, you may also want to be aware of electrical code and other safety considerations. Most commonly, new residential and commercial installations, as well as significant renovations, will be subject to fire marshal inspections during which compliance of all electrical components is a must-have.

E.g.: In the United States, the primary rules and regulations for electrical standards stem from the National Electrical Code. LED strip lights generally fall under the "low voltage lighting systems" category under NEC article 411. The key consideration here is that article 411 requires the use of a listed, Class 2 power supply.

A listed, Class 2 power supply will generally need to meet two requirements:

1.The power output is limited to 60 volts, 4 amps and 100 watts

2.The power supply has been tested for safety and Class 2 performance requirements and is listed with a certification laboratory such as UL

The key consideration here is the 100 watt limit, where no circuits can exceed 100 watts at any point. Therefore, the practical recommendation here is to use one Class 2 power supply per reel (5mts) of LED strip lights, as this ensures that we stay within the Class 2 requirements under NEC article 411 and allow the LED strip light installation to pass any electrical and fire safety inspections.

Putting it All Together

LED strip light installations can get a bit tricky, especially as the magnitude of the installation increases. Many installations will need to adhere to all three of the LED strip run length constraints we've discussed today, and thoroughly understanding each of these constraints will be helpful prior to finalizing your LED strip layout proposal.

Do you need information on HOLALUX products or services ?